Ready for the push at the point of sale.

We have been manufacturing displays made of plastic, metal, wood and cardboard for almost fifteen years. We are happy to assist you with your project, from prototyping to placement. Our service includes the following production options: Injection molding, thermoforming, plastic extrusion, metal & wire processing, digital & screen printing, bending & bonding of plastics as well as packaging.

We are open to any project, whether small or large series. You are also welcome to contact us for individual items.

Laser cutting

Digital printing

CNC portal milling machine

Edging & bending

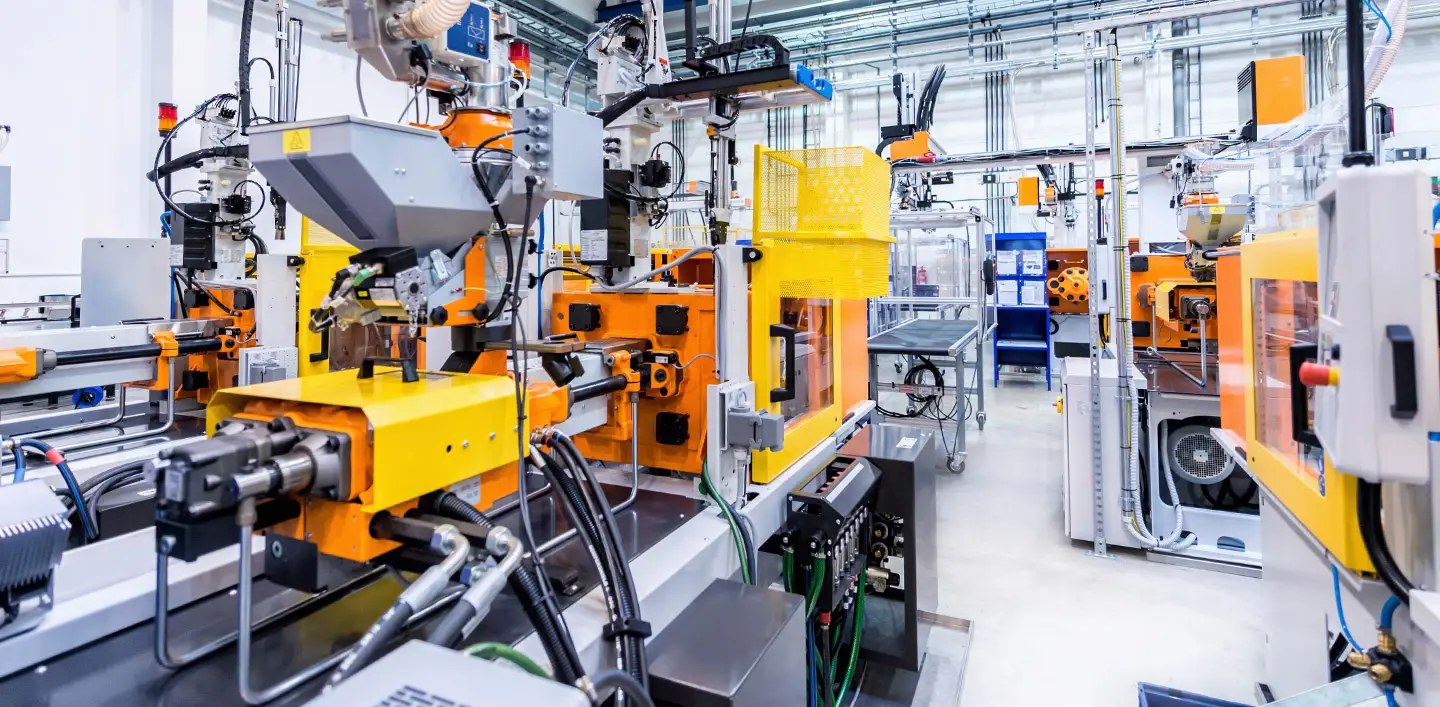

Injection molding

Metal processing

FAQ-PRODUCTION TECHNIQUES

The procedure

Injection molding technology is often also referred to as injection molding or injection molding process. This primary molding process is mainly used in plastics processing. In this type of production, plastic pellets are liquefied and injected into a metal mold under high pressure. A subsequent cooling period ensures that the plastic retains its desired shape.

The advantages

This process makes it possible to produce directly usable molded parts in large quantities at low prices. The production speed also stands out, especially for large orders.

No further processing of the finished plastic parts is necessary. Surface and color parameters are defined in advance. The accuracy and robustness of the finished parts is another feature that speaks for injection molding production.

The procedure

Liquid plastic is pressed through a nozzle using pressure and heat. This produces endless profiles such as price or scanner rails. Unlike injection molding technology, this process produces elongated two-dimensional shapes. The profile in the nozzle determines the shape.

Advantages

With this process, bodies of almost any length can be produced. You decide whether the profile should be split after a few millimetres or several meters. The start-up costs are comparatively low and the service life of the nozzle is very long.

The procedure

A plastic sheet is first heated until it becomes malleable. The plastic is then sucked into a negative mold using a vacuum. After a defined cooling time, the plastic hardens and retains its shape.

Polystyrene, PVC and PET sheets in various material thicknesses are processed using this method.

Advantages

Individual design at comparatively low-cost conditions. Smaller quantities can also be realized with this process.

The procedure

Various sheet materials are shaped by sawing, bending and edging and then processed into a wide variety of end products. A wide range of acrylic products are manufactured in this way (L-shaped stands, bags, menu card holders).

The advantages

Single or very small quantities can be produced promptly. Short start-up times and high scalability guarantee a fair price structure.

The procedure

Metal wire can be formed into the desired shape using a wide variety of processing techniques. Fully automated wire bending machines form the basis for hooks, brochure holders and other accessories for displays. In addition, the wire can then be given a coating of your choice (chrome, powder, lacquer).

Advantages

Shaped wire is extremely stable and durable. Consistent quality can be guaranteed. This production process is ideal for the production of display accessories.

The procedure

In this printing process, large-format panels (2500mm x 1250mm) are printed with a durable UV ink. The ink is cured immediately by a built-in UV lamp. The printed panels (acrylic, PET, wood, etc.) can then be further processed.

Advantages

The printed image in this printing process is extremely detailed and color-intensive. This is why digital printing is often used at the point of sale. Bright colors attract attention. Added to this are the low start-up costs. Digital printing is therefore also ideal for individual items, samples and short runs.

The procedure

The screen printing process is one of the stencil printing processes. The desired print is transferred to a stencil using UV light. During the printing process, the ink is then pressed through the stencil onto the printed material. A separate screen is required for each process color (CMYK, spot colors).

The advantages

The screen printing process is specially designed for larger quantities. The ink is extremely resistant to mechanical influences and UV radiation. Special colors (RAL, Pantone) can also be used in the printing process.